Machine Vision System For Tool Wear Assessment

The invention discloses a rotational cutting tool state multiple parameter overall assessment method based on image identification belonging to the technical field of electronic measurement. This paper describes the development of a machine vision system for automated tool wear inspection.

A Machine Vision System For Micro Milling Tool Condition Monitoring Sciencedirect

A new parametric approach for the assessment of comprehensive tool wear in coated grooved tools Annals of the ClRP 44 1995 49-54.

Machine vision system for tool wear assessment. A machine vision system for tool wear assessment Triblogy International vol. 30 issue 4 1997 295-304. 2734 Lmpixel Vertical factor.

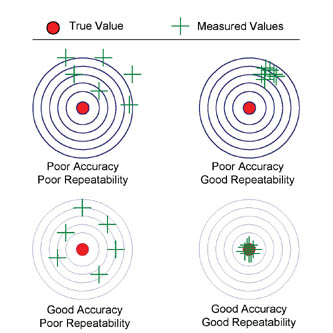

On-machine experiments were carried out to test the effect of this method. Calculating the abrasion area of. Such a system characterized by its measurement flexibility high spatial resolution and good accuracy is presented here.

Pearson and Slaughter 1996 developed a machine vision Assessment of vegetables system for the detection of early split lesion on the hull of pistachio nuts and reported that the developed system Computer vision has been shown to be a viable approach classified early split nuts with 100 success and normal to inspection and grading of. Design and Assessment of a Machine Vision System for Automatic Vehicle Wheel Alignment articleFurferi2013DesignAA titleDesign and Assessment of a Machine Vision System for Automatic Vehicle Wheel Alignment authorR. Therefore a tool condition monitoring TCM system is highly desirable for ultrasonic metal welding.

Various lighting systems were tested. Tool wear monitoring is an integral part of modern CNC machine control. Direct methods are based upon direct measurements of the tool wear using optical radioactive electrical resistance proximity sensors or vision system etc.

Direct sensing method and Indirect sensing method. Machine vision technique is an advanced method for tool wear monitoring. A machine vision system for gauging calculates the distances between two or more points or geometrical locations on an object and determines whether these measurements meet specifications.

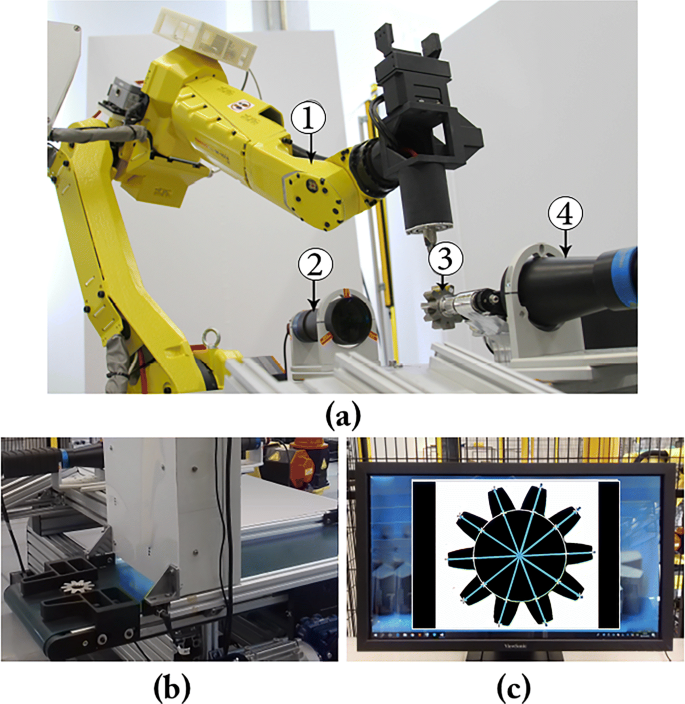

If not the vision system sends a fail signal to the machine controller triggering a. 296 Tribology International Volume 30 Number 4 1997 Machine vision system for tool wear assessment. In this article a holding system has been designed and fabricated to realize the combination of machine tools and machine vision system.

Work deals with design and assessment of a 3D machine visionbased system for the contactless reconstruction of vehicle wheel geometry with particular reference to characteristic planes. Bradley CCD Camera Microscope Extension Horizontal factor. In micro-tool imaging this problem is compounded with the need for high magnification lenses.

The concrete steps are as follows. A reliable and clear cutting tool surface image is obtained by high speed rotational cutting tool transient image capture based on CCD. Unsteady illumination may cause pixel distortions and a lack of consistent images causing an erroneous wear detection system.

The proposed approach measures the tool wear region based on the active contour algorithm and classifies the wear type by means of neural networks. In addition tool replacement including horns and anvils constitutes an important part of production costs. One of the main components of a machine vision system is a good source of consistent light.

Such planes properly referred to as a global coordinate system are used for determining wheel angles. Tool wear has a significant impact on joining quality. Kurada and Bradley did a pioneering work to direct monitoring of tool status based on machine vision technology they used two fibre-optic light source combine with a CCD camera to obtained tool wear image calculate the flank wear by preprocessing and binarized image method propose tool life criteria to quantitative analysis wear information but the tool image is not captured on-machine and.

Read 101016S0301-679X9600058-8 on DeepDyve the largest online rental service for scholarly research with thousands of academic publications available at your fingertips. Carfagni journalInternational Journal of Advanced Robotic Systems year2013. Cutting tools must be periodically checked for possible or actual premature failure Assessment and visualisation of machine tool wear using computer vision SpringerLink.

During monitoring the tool is positioned such that the camera can focus on its flank face and a typical image of the tools clearance face obtained is shown in Fig. Modern image processing techniques and machine vision systems can now enable direct tool wear measurement to be accomplished in-cycle. Commonly used tool wear sensing methods can be classified in to two main categories.

A Review On Tool Wear Monitoring System

A Review On Tool Wear Monitoring System

A Machine Vision System For Micro Milling Tool Condition Monitoring Sciencedirect

A Machine Vision System For Micro Milling Tool Condition Monitoring Sciencedirect

Implementation And Potentials Of A Machine Vision System In A Series Production Using Deep Learning And Low Cost Hardware Sciencedirect

Did You Know That Most Vision Problems Are Preventable It S True And We Have Some Great Tips To Help You Ke Eye Health Vision Problems Effects Of Sleep Apnea

A Machine Vision System For Micro Milling Tool Condition Monitoring Sciencedirect

Pdf Development And Application Of A Machine Vision System For Measurement Of Tool Wear

A Machine Vision Algorithm For Quality Control Inspection Of Gears Springerlink

Pdf Development And Application Of A Machine Vision System For Measurement Of Tool Wear

Machine Vision Theory Algorithms Practicalities Signal Processing And Its Applications Davies E R 9780122060939 Amazon Com Books

Pdf Measurements Of Tool Wear Parameters Using Machine Vision System

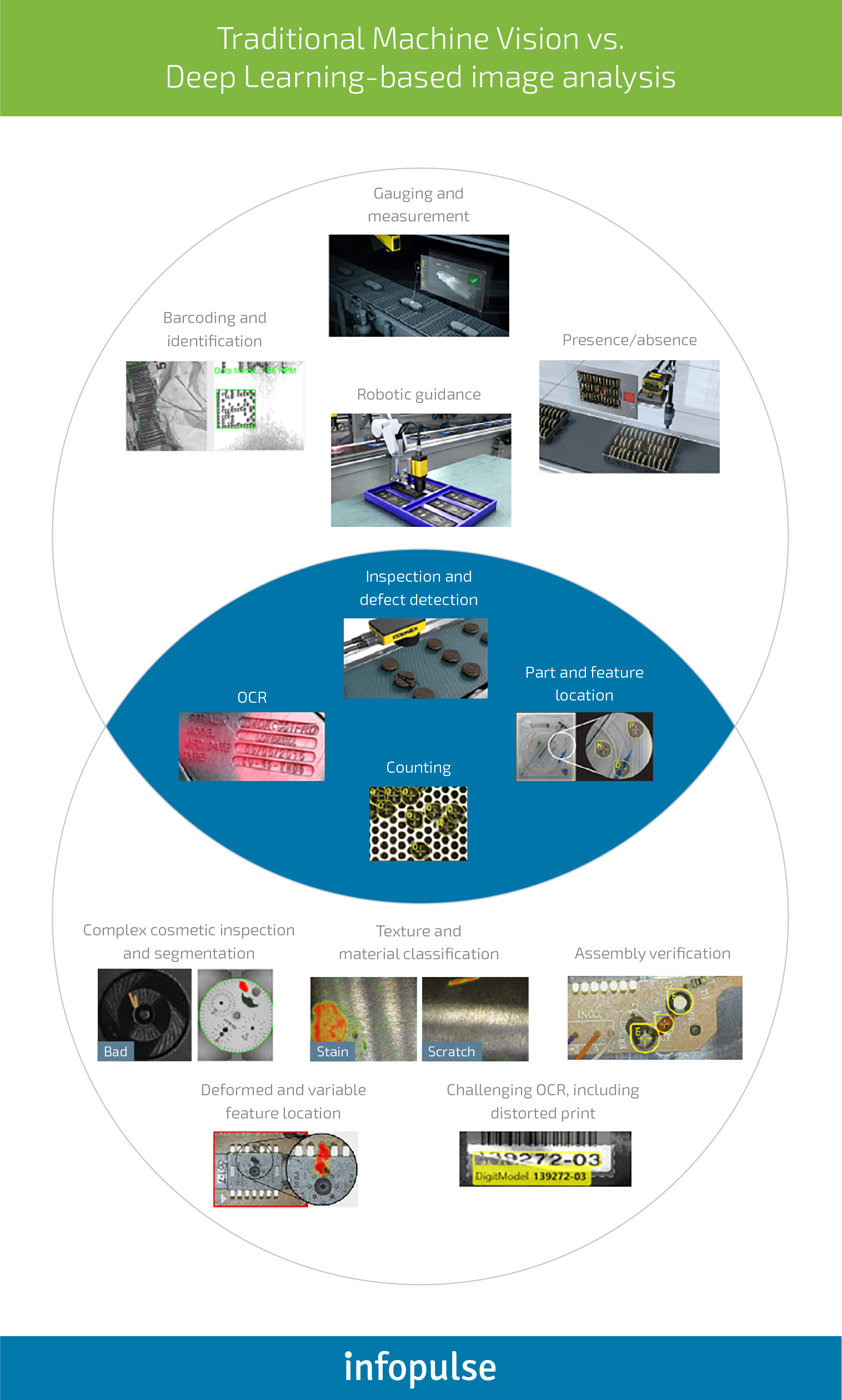

Intelligent Defect Inspection Powered By Computer Vision And Deep Learning Infopulse

Implementation And Potentials Of A Machine Vision System In A Series Production Using Deep Learning And Low Cost Hardware Sciencedirect

Machine Vision Makes Gaging Easy

A Machine Vision System For Micro Milling Tool Condition Monitoring Sciencedirect

Pdf A Survey On Industrial Vision Systems Applications And Tools

Lims Is A System Designed To Support Public Health National Reference Laboratories Laboratory Information Management System Interactive Tools Data Analysis

Pdf Development And Application Of A Machine Vision System For Measurement Of Tool Wear

Post a Comment for "Machine Vision System For Tool Wear Assessment"